Troubleshooting Common Issues in Industrial Slewing Ring Operation

2025.12.11

2025.12.11

Industry news

Industry news

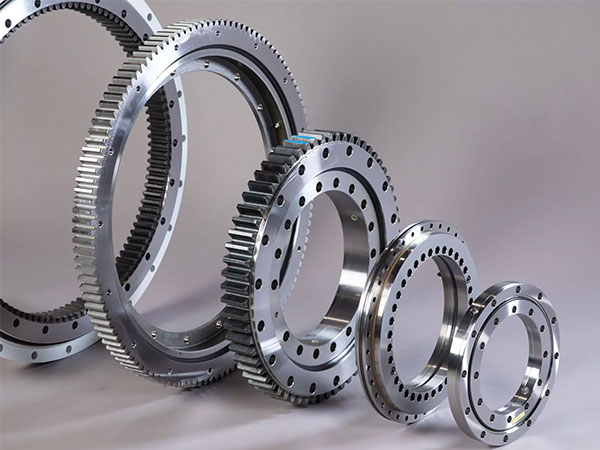

Industrial slewing rings are critical components in heavy machinery, cranes, excavators, and rotating platforms. Proper operation ensures reliability, precision, and safety, but issues can arise due to improper installation, insufficient maintenance, or operational overload. Understanding common problems and their solutions can extend the service life of slewing rings and reduce downtime in industrial applications.

Content

Identifying Common Operational Problems

Recognizing early signs of malfunction in slewing rings is essential for preventing major failures. Typical issues include abnormal noise, uneven rotation, excessive vibration, and uneven wear on bearing surfaces. Regular inspection and monitoring allow operators to address problems before they compromise machinery performance.

Symptoms to watch for

- Grinding or squeaking noises during rotation, indicating lubrication issues or debris in the bearing.

- Excessive vibration or uneven movement, which may result from misalignment or worn components.

- Visible cracks or deformation on the slewing ring, suggesting overloading or fatigue damage.

Lubrication and Maintenance Issues

Proper lubrication is vital to prevent friction, wear, and overheating in slewing rings. Neglecting lubrication schedules or using inappropriate grease can lead to premature failure. Routine maintenance, including cleaning and inspection, ensures smooth operation and long-term reliability.

Maintenance best practices

- Use manufacturer-recommended lubricants and follow the specified re-lubrication intervals.

- Inspect bearing surfaces for debris, corrosion, or pitting that can hinder smooth rotation.

- Ensure that grease fittings are clean and properly aligned to prevent contamination.

Alignment and Installation Problems

Incorrect installation or misalignment of slewing rings can cause uneven load distribution, leading to premature wear and operational inefficiency. Ensuring proper alignment during assembly and verifying bolt torque according to specifications are key steps in preventing these issues.

Installation considerations

- Confirm that the mounting surface is flat and free from debris to avoid uneven stress on the bearing.

- Tighten bolts evenly in a cross pattern to maintain uniform load distribution.

- Use alignment tools to verify that the inner and outer rings are concentric and properly seated.

Overloading and Operational Errors

Slewing rings are designed to handle specific radial, axial, and moment loads. Exceeding these limits can cause deformation, cracking, or premature wear. Operator training and adherence to load specifications are essential to prevent damage and maintain performance.

Preventing overload damage

- Refer to manufacturer load charts and never exceed recommended radial or axial capacities.

- Monitor machinery usage and avoid abrupt directional changes or excessive torque.

- Implement operational safety protocols and regular inspections to detect early signs of overload stress.

Corrosion and Environmental Concerns

Industrial slewing rings are often exposed to harsh environments, including moisture, dust, and chemicals. Corrosion or contamination can impair performance, reduce service life, and increase maintenance needs. Protective coatings and proper storage are effective strategies to mitigate environmental damage.

Environmental protection measures

- Apply corrosion-resistant coatings and lubricants designed for the specific environment.

- Store slewing rings in dry, clean areas to prevent exposure to moisture and contaminants.

- Regularly inspect seals, shields, and protective covers to maintain environmental protection.

Conclusion: Ensuring Reliable Slewing Ring Operation

Troubleshooting industrial slewing ring issues requires attention to lubrication, installation, alignment, operational limits, and environmental protection. By understanding common problems and implementing proactive maintenance practices, operators can extend service life, enhance safety, and maintain optimal performance in heavy machinery applications.