Selecting the Right Lubrication and Sealing for Single Row Cross-Roller Bearings

2025.12.18

2025.12.18

Industry news

Industry news

Content

Selecting the Right Lubrication and Sealing for Single Row Cross-Roller Bearings

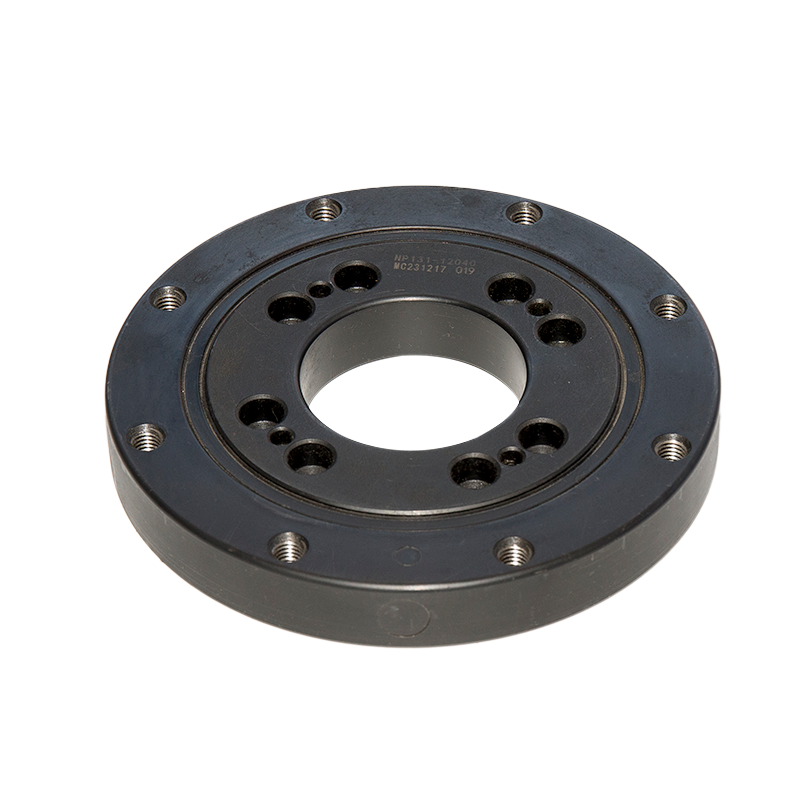

Proper lubrication and sealing are critical for the optimal performance and longevity of Single Row Cross-Roller Bearings. These bearings are designed to handle high-precision rotational loads while maintaining rigidity and accuracy. Inadequate lubrication or improper sealing can result in premature wear, increased friction, and even failure under heavy loads. Understanding the types of lubricants, their application methods, and compatible sealing solutions ensures reliable operation in industrial machinery, robotics, and heavy equipment.

Choosing the Appropriate Lubricant

Selecting the correct lubricant involves evaluating operational conditions such as load, speed, temperature, and environmental factors. For Single Row Cross-Roller Bearings, the two most common lubrication types are grease and oil. Grease provides excellent sealing and ease of maintenance, making it suitable for moderate speeds and loads. Oil lubrication, often through circulating systems, is preferred for high-speed or high-temperature applications where heat dissipation is critical.

Grease Selection

Grease must have adequate viscosity, thermal stability, and load-carrying capacity. Lithium-based greases are commonly used due to their wide temperature range and good mechanical stability. Polyurea greases provide superior oxidation resistance and are ideal for continuous operation under moderate to high loads. When selecting grease, consider the bearing’s rotational speed, operating temperature, and potential exposure to contaminants.

Oil Lubrication

Oil lubrication is typically used for high-speed or high-load applications, such as precision turntables or robotic arms. Mineral oils with anti-wear additives are common, but synthetic oils may be required for extreme temperatures or long maintenance intervals. Circulating oil systems ensure consistent lubrication and heat dissipation, reducing the risk of overheating and uneven wear. Oil also facilitates flushing of small debris, improving overall bearing cleanliness.

Sealing Solutions for Cross-Roller Bearings

Sealing prevents lubricant leakage and protects the bearing from contaminants such as dust, moisture, and metal particles. The choice of seals directly impacts bearing performance and maintenance frequency. Common sealing types include labyrinth seals, rubber contact seals, and metal shields. Each type provides a balance between contamination protection, rotational resistance, and service life.

Labyrinth Seals

Labyrinth seals offer non-contact protection with minimal friction, making them suitable for high-speed applications. They create a tortuous path that reduces contaminant ingress while retaining lubricant within the bearing. Labyrinth seals are effective against moderate dust and debris but may require supplemental lubrication if exposed to heavy contamination.

Rubber Contact Seals

Rubber contact seals provide a tighter barrier against contaminants by directly contacting the bearing surfaces. They are ideal for applications where dust, dirt, or moisture is prevalent. However, these seals introduce slightly higher friction and may require more precise alignment to avoid premature wear of the sealing lip.

Metal Shields

Metal shields are thin, durable covers that provide basic protection against contaminants while maintaining low rotational resistance. They are commonly used in moderate-speed applications where external contamination is limited. Shields can be combined with grease lubrication to extend bearing life and reduce maintenance frequency.

Maintenance Practices for Lubrication and Sealing

Regular maintenance ensures that lubrication and seals perform effectively throughout the bearing’s service life. Bearings should be inspected periodically for grease consistency, oil levels, and seal integrity. Contaminated lubricant must be replaced promptly to avoid accelerated wear. In addition, check for seal deformation, cracks, or excessive friction that could indicate failure. Establishing a maintenance schedule based on operating hours, load conditions, and environmental exposure helps prevent unexpected downtime and extends bearing life.

Comparison of Lubrication and Sealing Options

| Lubrication Type | Application | Advantages | Considerations |

|---|---|---|---|

| Grease | Moderate speed/load | Easy maintenance, good sealing | May require relubrication in high-speed applications |

| Oil | High-speed, high-load | Effective cooling, reduces friction | Requires circulation system, monitoring needed |

| Labyrinth Seal | High-speed, low contamination | Minimal friction, durable | Limited protection against heavy dust |

| Rubber Contact Seal | Dusty/moist environments | Excellent contaminant protection | Higher friction, wear potential on seal lip |

| Metal Shield | Moderate speed, low contamination | Low friction, durable | Limited contaminant protection |

Conclusion

Selecting the right lubrication and sealing for Single Row Cross-Roller Bearings ensures stable operation, reduces maintenance frequency, and extends service life. By matching grease or oil type to operational requirements and choosing seals appropriate for environmental conditions, engineers can maximize performance and reliability. Regular maintenance, inspection, and timely replacement of lubricants or seals are essential to prevent premature wear and maintain precision in high-performance rotational systems.