Single Row Cross-Roller Slewing Bearing: Design, Applications, and Maintenance Guide

2026.02.11

2026.02.11

Industry news

Industry news

Content

- 1 Introduction to Single Row Cross-Roller Slewing Bearings

- 2 Structure and Design Features

- 3 Advantages of Single Row Cross-Roller Slewing Bearings

- 4 Applications of Single Row Cross-Roller Slewing Bearings

- 5 Selecting the Right Bearing

- 6 Maintenance Practices

- 7 Comparison of Common Slewing Bearing Types

- 8 Conclusion

Introduction to Single Row Cross-Roller Slewing Bearings

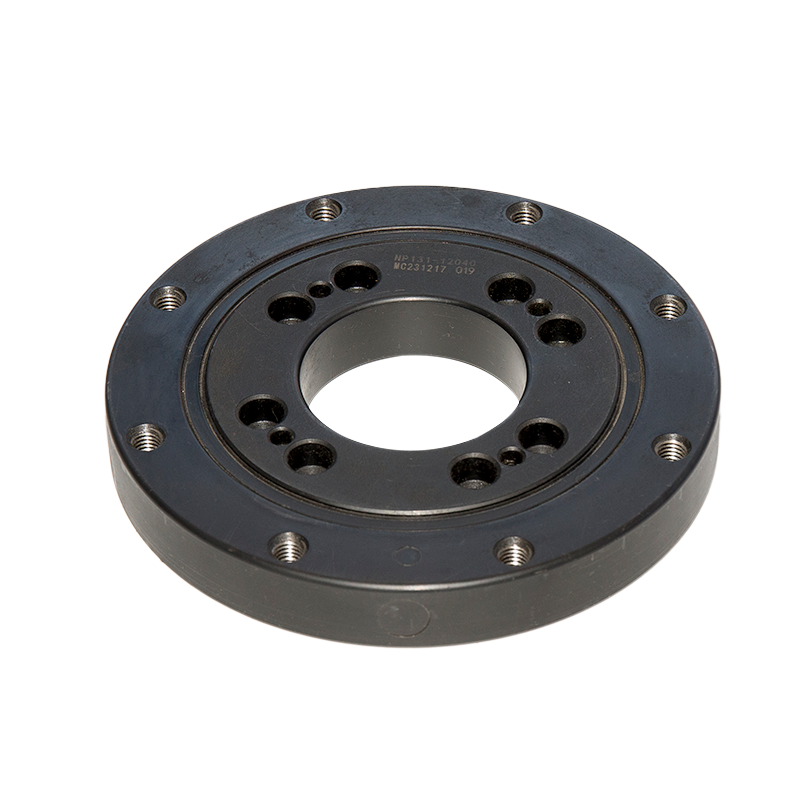

Single row cross-roller slewing bearings are high-precision, compact rotational components used in a wide range of industrial machinery. They feature a unique arrangement of cylindrical rollers that cross at right angles, allowing the bearing to handle radial, axial, and tilting moment loads simultaneously. These bearings are widely applied in robotics, cranes, construction machinery, and turntables due to their high rigidity, smooth rotation, and space-saving design.

Structure and Design Features

The design of a single row cross-roller slewing bearing is key to its performance. The bearing consists of an inner ring, outer ring, and cross-arranged cylindrical rollers held by a cage or separator. This structure allows the rollers to evenly distribute loads, ensuring stability and long service life.

Cross-Roller Arrangement

The cylindrical rollers are arranged alternately at right angles to each other. This configuration allows the bearing to carry loads in all directions, including combined radial, axial, and tilting moment loads. This makes the bearing suitable for applications where space is limited but high load capacity is required.

Cage Design

The rollers are separated by a cage, which ensures uniform spacing and reduces friction. Common cage types include metal and polymer cages, each offering benefits such as improved lubrication distribution, reduced wear, and enhanced rotational accuracy.

Advantages of Single Row Cross-Roller Slewing Bearings

Single row cross-roller slewing bearings offer several key advantages over traditional bearings, making them ideal for precision and heavy-load applications:

- High load capacity in radial, axial, and tilting directions.

- Compact design that saves space while maintaining strength.

- High rotational accuracy and smooth operation for precise motion control.

- Durable construction for long service life in harsh environments.

- Versatility in application, suitable for both static and dynamic loads.

Applications of Single Row Cross-Roller Slewing Bearings

These bearings are widely used in machinery requiring both precision and load capacity. Typical applications include:

- Industrial robots for precise rotational movement of joints.

- Cranes and lifting equipment requiring support for heavy axial and radial loads.

- Construction machinery such as excavators and loaders.

- Rotary tables and turntables used in manufacturing or assembly lines.

- Medical equipment and imaging systems requiring smooth, accurate rotation.

Selecting the Right Bearing

Choosing the appropriate single row cross-roller slewing bearing depends on load requirements, rotational speed, environmental conditions, and installation constraints. Key selection criteria include:

Load Ratings

Determine the maximum radial, axial, and tilting moment loads the bearing will carry. Ensure the selected bearing can handle peak loads without excessive deflection or reduced service life.

Rotational Accuracy

For precision machinery, consider bearings with high rotational accuracy. Tolerance classes and preloading can influence motion smoothness and repeatability.

Material and Surface Treatment

Common materials include high-grade alloy steel with heat treatment for hardness and wear resistance. Surface treatments, such as nitriding or coating, improve corrosion resistance and extend bearing life, especially in outdoor or humid environments.

Maintenance Practices

Proper maintenance ensures reliable performance and long service life. Essential practices include:

- Regular lubrication with the recommended grease or oil to reduce friction and wear.

- Periodic inspection for abnormal noise, vibration, or heat generation.

- Checking and tightening mounting bolts to maintain alignment and load distribution.

- Monitoring for corrosion or surface damage and applying protective coatings if needed.

- Replacing bearings if excessive wear or fatigue is detected to prevent machine failure.

Comparison of Common Slewing Bearing Types

Single row cross-roller slewing bearings can be compared with other common types to determine the best solution for a given application.

| Bearing Type | Load Capacity | Precision | Applications |

|---|---|---|---|

| Single Row Cross-Roller | High radial, axial, and moment loads | High | Robotics, cranes, turntables |

| Four-Point Contact | Moderate axial and radial loads | Medium | Rotary tables, solar trackers |

| Double Row Cross-Roller | Very high combined loads | High | Heavy machinery, large cranes |

Conclusion

Single row cross-roller slewing bearings are essential components for high-precision and heavy-load applications. Their compact design, high rigidity, and ability to handle combined loads make them ideal for robotics, cranes, and construction machinery. Proper selection, installation, and maintenance ensure long-lasting performance, efficiency, and safety, making these bearings a reliable choice for modern industrial equipment.