How Do Crossed Cylindrical Rollers Improve Load-Bearing Capacity Compared to Other Bearing Types?

2025.09.22

2025.09.22

Industry news

Industry news

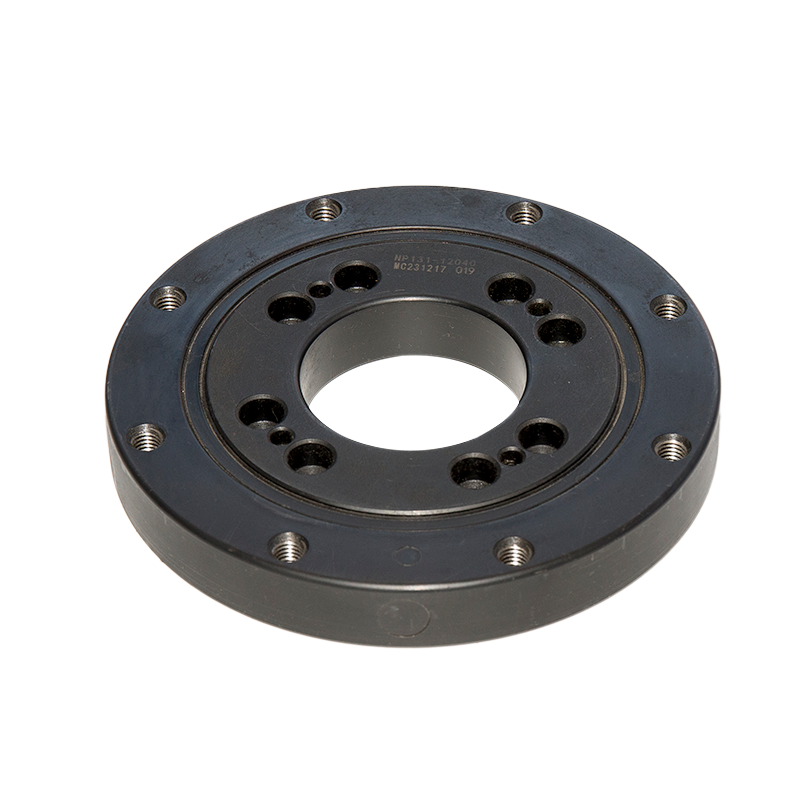

Slewing bearings play a critical role in heavy machinery and precision equipment, where they are responsible for supporting large loads while allowing smooth rotational or oscillatory motion. Among the different bearing designs, the single row cross-roller slewing bearing stands out due to its unique arrangement of cylindrical rollers set at right angles to each other. This structural design provides performance advantages that traditional ball bearings or standard roller bearings cannot easily match.

Content

1. Structural Difference Between Ball and Cross-Roller Designs

- Ball bearings use point contact between balls and raceways. While they can handle both radial and axial loads, the contact area is relatively small. Under heavy loads, the stress is concentrated at those points, which can lead to deformation.

- Standard cylindrical roller bearings use line contact, which provides greater load capacity than ball bearings. However, they are typically designed to handle loads in primarily one direction (radial) and are less effective with combined or complex loading conditions.

- Crossed cylindrical roller bearings place rollers at 90 degrees to each other in alternating orientation. Each roller makes line contact with the raceway, but because of the crossed arrangement, the bearing can carry axial, radial, and tilting moment loads simultaneously.

This cross-roller geometry is what gives the design its exceptional load-bearing ability.

2. Larger Contact Surface and Reduced Stress

The use of cylindrical rollers inherently increases the contact surface compared to balls. Instead of relying on a small point of contact, each roller engages with the raceway along a line. This spreads the load over a wider surface area, reducing stress concentration and lowering the risk of material fatigue or deformation.

When these rollers are arranged in a crossed pattern, the load distribution becomes even more balanced. This means that heavy or uneven loads are more efficiently absorbed, giving the bearing a much higher load capacity relative to its size.

3. Ability to Withstand Multi-Directional Loads

One of the most important benefits of crossed cylindrical rollers is their ability to support multi-directional forces simultaneously.

- Axial loads: The vertical load applied along the axis of rotation.

- Radial loads: The horizontal load acting perpendicular to the axis.

- Tilting moment loads: Forces that create torque or bending stress around the bearing.

While standard bearing types are often optimized for one or two of these load directions, a single row cross-roller slewing bearing can handle all three at once without compromising performance. This makes it particularly valuable in applications like cranes, excavators, wind turbines, robotics, and precision machine tools, where complex and unpredictable loading conditions are common.

4. Higher Rigidity and Stability

Because the rollers are tightly arranged and alternate at right angles, the bearing exhibits greater rigidity than ball-based designs. This rigidity minimizes deflection under heavy loads, which is essential for equipment requiring both strength and precision. For example:

- In construction machinery, it prevents unwanted movement in slewing platforms.

- In industrial robots, it enhances positioning accuracy during repetitive, high-load cycles.

5. Space and Weight Efficiency

Another advantage is that cross-roller slewing bearings can achieve high load capacity with a compact structure. Instead of using larger or multiple bearings to handle different load directions, a single cross-roller bearing can do the job. This reduces both the weight and the space required, which is especially valuable in equipment where compact design is essential.

6. Comparison Summary

- Ball bearings → Lower load capacity, mainly point contact, good for lighter applications.

- Standard roller bearings → Higher radial load capacity, but limited ability to handle axial or moment loads simultaneously.

- Crossed cylindrical roller bearings → Line contact with crossed orientation, excellent at handling axial, radial, and tilting moment loads all in one compact bearing.

Conclusion

Crossed cylindrical rollers significantly improve load-bearing capacity compared to ball and standard roller bearings because of their line contact, cross arrangement, and ability to carry multi-directional loads simultaneously. This combination of strength, rigidity, and efficiency makes single row cross-roller slewing bearings indispensable in industries ranging from heavy equipment to high-precision robotics.

By reducing stress concentration and providing greater stability, they not only extend the service life of machinery but also enhance performance in demanding applications where other bearing types might fall short.